PRODUCTION

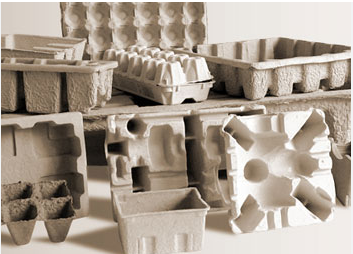

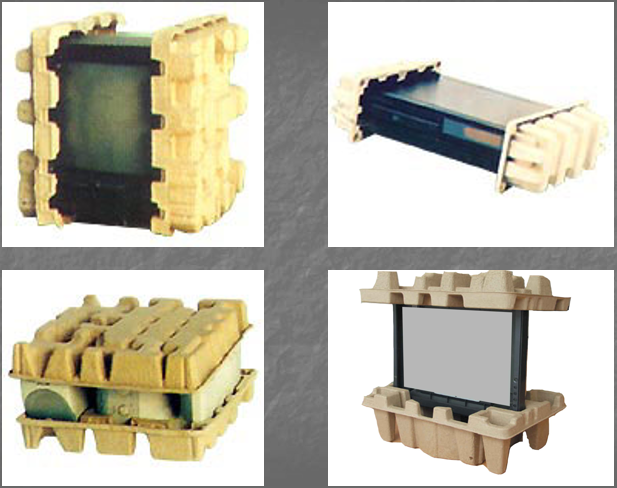

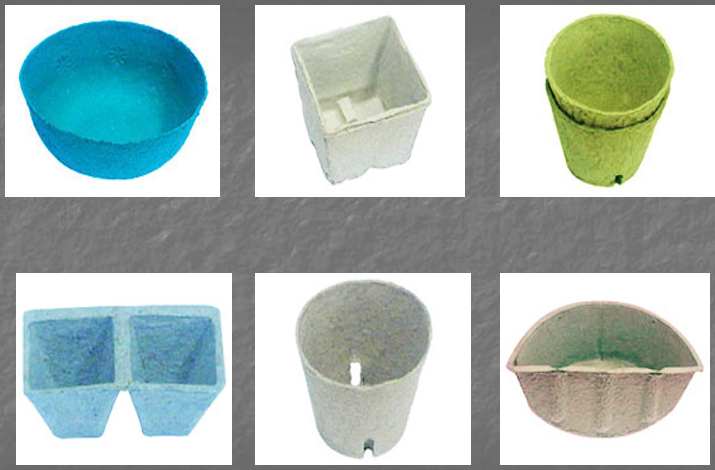

Molded pulp packaging, also referred to as viyol production, is a process of shaping paper pulp using molds specifically designed for each product. The dimensions of many products are more complex than a simple cube. Molded pulp packaging is a material that allows for deep cavities to be created to protect the most fragile corners and protrusions of your product while providing exceptional flexibility.

Product design, mold manufacturing, and the production process are all specialized and require know-how. Various plant pulps such as recycled paper, reed pulp, and sugarcane pulp can be used in molded paper packaging production. Viyol packaging has the capability to process 100% recycled paper as well as virgin paper pulp.

Molded paper packaging production is suitable for medium to high-volume production. Molded paper packaging products are typically gray as a standard but can be produced in different colors when required.